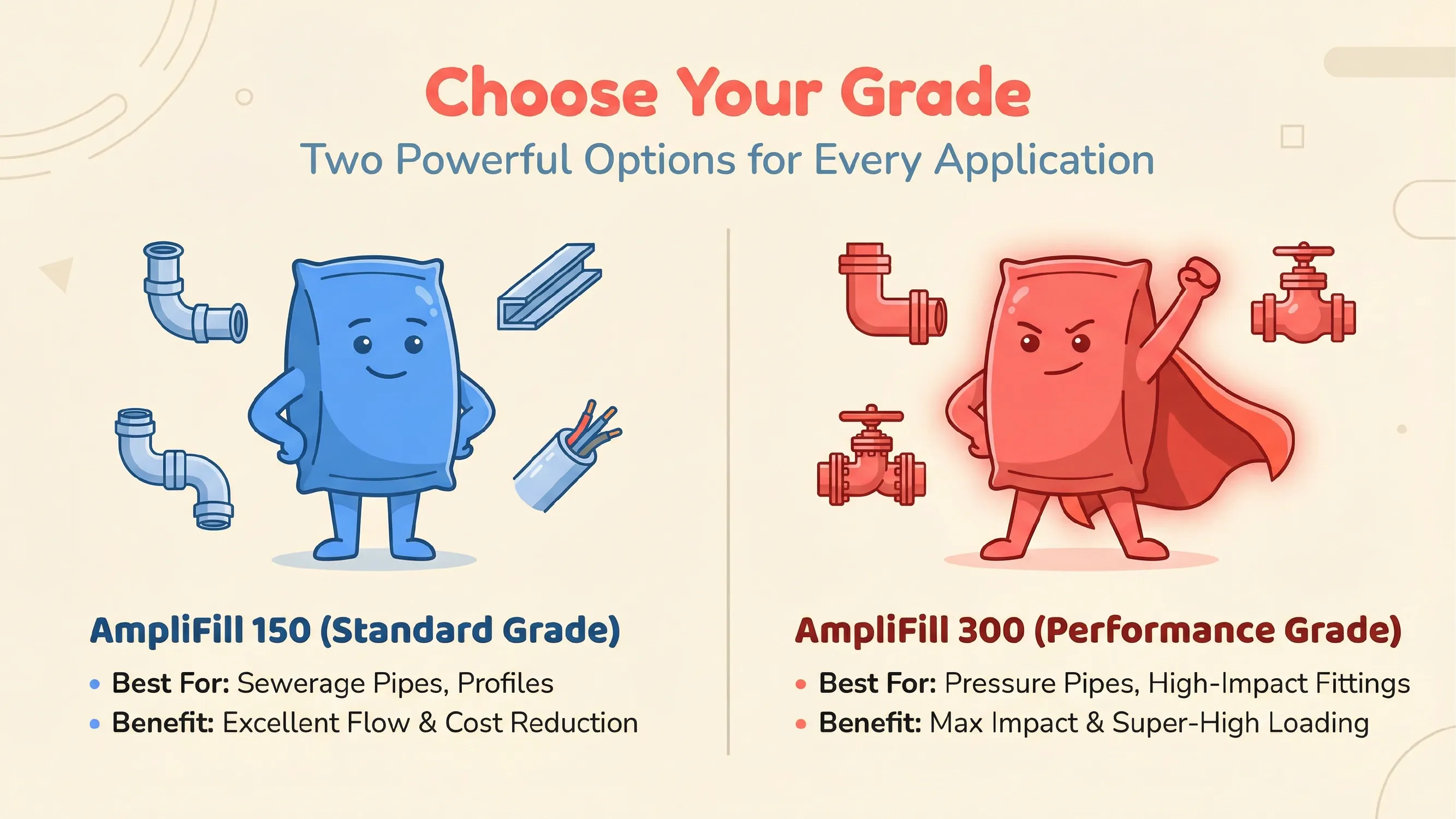

Select Your Grade

Both AmpliFill grades deliver the same exceptional results—just at different dosages. Your choice depends on your end-use application and density standards requirements.

AmpliFill Benefits

Both grades provide these exceptional benefits for your PVC production.

Maximum Impact Resistance

Maintain or improve impact strength even at higher filler loadings

Super-High Loading Capacity

Increase filler loading by 20-50% without compromising quality

Premium Surface Finish

Achieve excellent surface quality for demanding applications

Excellent Flow Properties

Improved melt flow for easier processing and faster cycles

Extended Equipment Life

Reduced wear on screws, barrels, and dies

Consistent Quality

Batch-to-batch consistency for reliable production

How to Choose

Both grades deliver identical results. The key difference is dosage—AmpliFill 300 is used at half the dosage of AmpliFill 150. Your selection depends on your application's density requirements.

Understanding Density Standards

CaCO3 and AmpliFill share the same density (~2.7 g/cm³), which is significantly higher than PVC (~1.4 g/cm³). When increasing filler loading, the overall compound density increases.

Producers must balance maximum allowed density in standards with maximum filler loading for optimal cost reduction.

AmpliFill 150

Lower cost, higher dosage

Select when:

- Producing low-pressure pipes and fittings

- Density standards are more flexible

- Cost reduction is the primary goal

- Applications: Sewerage, Electrical Conduits, Window Profiles, Cable Ducts

AmpliFill 300

Half the dosage of 150

Select when:

- Strict density standards must be met

- Producing pressure-rated products

- Overall density must be maintained within specifications

- Applications: Pressure Pipes, Injection Moulding, Premium Profiles

The Bottom Line: Select your grade based on your end-use application and the density standards you must meet. Both grades enable maximum cost reduction through increased filler loading while maintaining the highest quality.